What We Produce

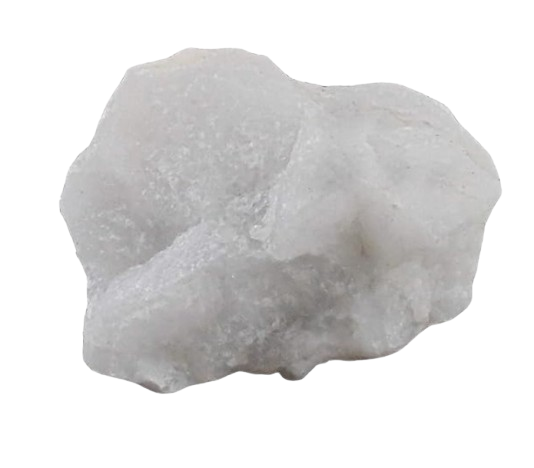

Quartz

The high-purity quartz deposits found in select global locations, such as regions in Brazil, the United States, and parts of Africa, are among the most sought-after raw materials for advanced industries. These resources are critical for manufacturing electronics, glass, solar panels, and specialized ceramics, thanks to their exceptional chemical and physical properties.

Quartz is often referred to as the “foundation mineral” for modern technology, playing an essential role in numerous industrial and renewable energy applications. With the global shift towards sustainable technologies, demand for high-grade quartz is expected to rise sharply. Recycling and alternative materials will not be able to fully meet the growing need in sectors like semiconductors, photovoltaic cells, and fiber optics.

Industry research suggests that the demand for high-purity quartz could nearly double in the next two decades, driven by the rapid expansion of clean energy infrastructure and advanced manufacturing. Production for applications in solar energy and electronics will need to scale significantly to meet global sustainability targets by 2050. Without substantial investment in mining, processing, and supply chain expansion, shortages could emerge, impacting the pace of technology adoption and clean energy deployment worldwide.

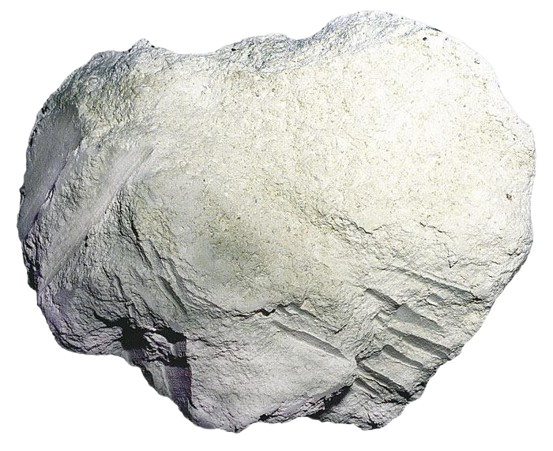

Kaolin

Kaolin, also known as china clay, is a vital industrial mineral extracted in regions such as the United States, Brazil, and parts of Asia and Africa. Renowned for its whiteness, chemical stability, and fine particle size, it is a key raw material in ceramics, paper coating, paints, and rubber manufacturing.

Often referred to as the “ceramic backbone,” kaolin’s unique properties make it essential for high-performance applications. As global demand for advanced ceramics, sustainable paper products, and eco-friendly coatings continues to rise, the kaolin market is projected to experience significant growth. Recycling and substitutes cannot fully meet demand in these specialized industries.

Market studies forecast a strong upward trend in kaolin consumption through 2050, driven by infrastructure growth, packaging needs, and industrial innovation. To meet future demand, mining and processing capacities must expand while maintaining strict environmental standards. Without proactive investment, supply constraints could hinder production in ceramics, construction, and paper industries worldwide.

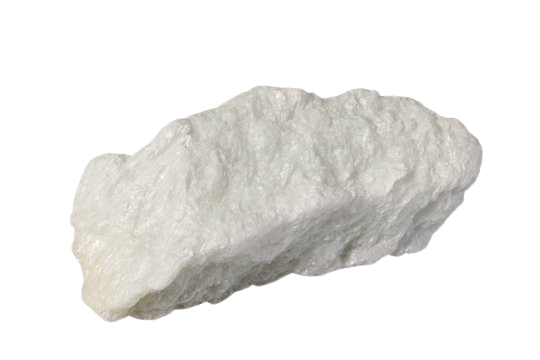

Talc

Talc, a naturally occurring mineral composed mainly of magnesium, silicon, and oxygen, is mined in countries such as China, India, and the United States. Its softness, chemical inertness, and ability to absorb moisture make it indispensable in ceramics, paints, plastics, cosmetics, and pharmaceuticals.

Known as the “softest mineral on Earth,” talc plays a critical role in enhancing product quality, durability, and performance. Global demand is expected to grow steadily, especially in manufacturing sectors, personal care products, and industrial coatings. Alternative materials cannot fully replace talc’s unique characteristics.

Industry analysts project increasing talc requirements over the next few decades, with demand closely tied to construction growth, automotive production, and rising consumer goods markets. Expanding mining and refining operations while ensuring safety and environmental compliance will be key to meeting global needs without disruption.

Feldspar

Feldspar, one of the most abundant minerals in the Earth’s crust, is primarily mined in countries like Turkey, Italy, China, and India. It is an essential raw material in the production of glass, ceramics, enamels, and other industrial applications due to its fluxing properties that lower melting temperatures.

Often called the “industrial melting aid,” feldspar improves strength, durability, and finish in ceramic and glass products. With global construction, infrastructure, and consumer goods markets expanding, feldspar demand is set to rise significantly. Recycled materials and substitutes cannot fully meet the specific requirements for high-quality applications.

Forecasts indicate strong demand growth for feldspar through 2050, fueled by rapid urbanization, the renewable energy sector, and advances in glass manufacturing. Increasing mining efficiency, processing capabilities, and sustainable practices will be crucial to ensuring stable supply for industries worldwide.